Windows and Insulated Glass

Glass and IGU’s

Windows connect our indoors with the outdoors through a seemingly miraculous transparent technology. Windows allow views, ventilation and light to enter while keeping bugs and weather out. Thanks to windows we have a home that would otherwise just be a fancy cave.

By building windows into the walls, they have become permanent parts of the infrastructure and architecture of our homes. Modern windows are not passive either. They have jobs to do to help the entire structure succeed. Operable units must open, close and lock. The window must provide insulation, sun protection and look good while doing it. Windows are also critical safety routes to escape from bedrooms in the event of fire or other emergency. As a result, building codes require that windows in those areas conform to certain sizes and configurations to allow human passage or “egress”.

Windows are important to both homes and homeowners.

History

Mankind’s use of glass for windows has a long history going back maybe 6000 years. The earliest known windows were made from assembling small pieces of glass. These pieces created a panel barely large enough to allow light in and be useable, but it was cool! This first technique continues to this day in the form of leaded, or stained-glass windows. The process has actually become very popular and the best examples are made by highly skilled artists.

Glass was so highly valued in early times that the British government levied a tax on it. When people moved from their homes, they might leave the oak furniture behind, but they would always take the windows with them. Bill Bryson’s book At Home provides a well researched and interesting look at the history of glass. See my review and get a copy here. It’s a fun read and I highly recommend it.

Plate Glass

The flat, or plate glass that we are familiar with today only became available in the middle 1800’s. And then it was only available in very small batches. True mass production of glass did not occur till the Ford Motor Company invented “continuous ribbon” production in the 1920’s.

Modern glass manufacturing can now create amazing shapes and just about any size that is transportable. I recommend you read the making of The Hubble Space Telescope, the design of Apple Computer’s retail stores, and the Grand Canyon “Skybridge,” if you are interested in the miraculous possibilities with glass engineering. All of these are amazing examples of extreme engineering with glass.

To-Do

- Be careful if you add aftermarket, tinting films to dual-glazed windows. Doing so will void nearly all manufacturer warranties. Apparently film can cause damage from excessive heat build-up between the panes of glass. Refer to the manufacturer s literature for additional information.

- Keep patio door and sliding window tracks clean for weep hole drainage, smooth operation and to prevent damage to the door frame.

- Label each screen if you intend to remove and store them. Handle them carefully as they can perforate easily and the frames are delicate and bendable.

Maintenance

- 1x per year: Clean and lubricate the sliding or cranking mechanisms. Silicone lubricants work well for these tracks and rollers. Most sliding windows (both vertical and horizontal) are designed to require a 10-pound pull force. If sticking occurs, or excessive pressure is required to open or close a window, apply a food grade silicone lubricant available at hardware stores. Avoid petroleum-based products.

- 1x per year: Keep the operable window channel weep holes clear. In heavy rains, water may collect in the bottom channel of window frames. The makers provide weep holes to allow water to escape to the outside. Keep these bottom window channels and weep holes free of dirt and debris.

- 1x per year: Check the hardware and locks as they should operate with reasonable ease and locks should perform as designed.

Window Configurations

Today, homeowners have many different types and styles of windows to choose from. The basic residential configurations are as follows. Fixed panel (non-moveable) sliding (opens by sliding sideways in a track), double-hung (these are stacked windows that both open by sliding up or down vertically). There are also, single hung (stacked pairs of windows where only the lower half is moveable) casement (these crank, or push open and are hinged from one side or the other) and awning (these crank, or push open and are hinged from the top). If I missed some, kindly let me know and I will add them to this list later.

Up until the 1960’s all windows consisted of a single pane (layer). These allowed light and blocked the wind fine but provided little in the way of thermal insulation value. To make up for that, homes in cold climates were often cleverly fitted with storm windows. These provided a second (insulating) layer of protection over the single pane windows. The storm windows would be removed in summer and replaced with a screen. As a result, twice a year screens and storm windows had to be handled, stored and protected from damage when not in use. The idea performed well, but was labor intensive, time consuming and inconvenient. Nevertheless, the system effectively served the purpose of adding an insulation layer when needed.

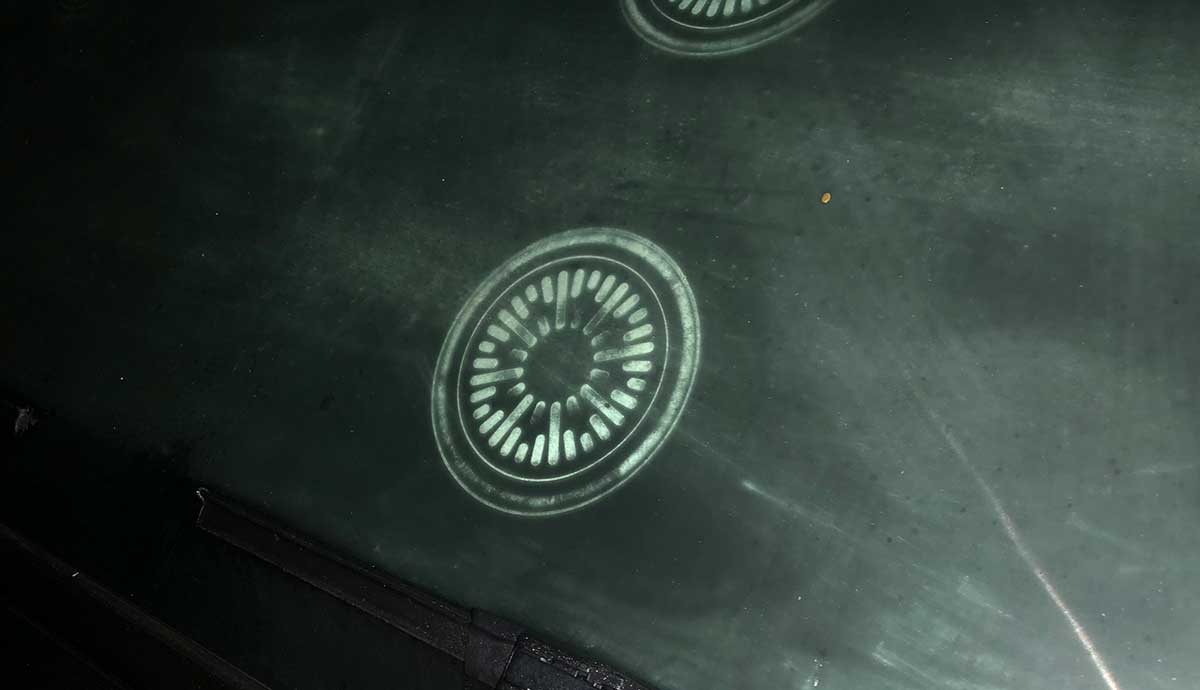

Insulated Glass Units-IGU’s

After the oil embargo in the 80’s, conservation suddenly became important. As a result, building departments quickly enacted codes requiring window designs to be more energy efficient. One solution was to copy the old storm window idea. Make window panels using two panes of glass with a sealed air space sandwiched in-between. The trapped air would create a thermal break just like the early storm windows only better. As a result, the first insulated glass units or IGU’s were developed. Early IGU’s were plagued by failures of the seals between the two sheets of glass. These failures would cause the windows to “fog” up unattractively as shown in the photo below. Fortunately, seal technology has caught up and IGU’s are now considered reliable. They are currently the norm for nearly every glass window in the US.

Condensation problems

The invention of IGU’s provided two benefits to homeowners. First, glass could now helped provide insulation for the home, and second, they eliminated condensation on the interior of the glass during cold weather. Condensation was not just annoying, it caused lots of damage. Historically, condensation produced enough water to saturate window trim and finishes. This would actually cause dry rot to the window sill. This was a big problem in the past. As a result of, I personally believe the most valuable contribution provided by insulated windows was the elimination of condensation damage.

Unfortunately, IGU’s did not fully resolve the condensation issue. Homeowners with metal framed windows quickly noticed that our villain was back. Although it was not forming on the glass, it was forming on the inside of the metal frames. The solution was of course to provide an insulated or thermal-break frame. Insulated frames are used on virtually all metal windows today.

Thermal-Break Frames and More

Modern windows with thermal-break frames are now available in wood, aluminum, steel, vinyl or fiberglass and in nearly any shape. IGUs can be custom ordered to suit almost any need. Various thermal configurations are available and even special optical coatings to reduce damaging UV rays. Integrated blinds can also be ordered that come sandwiched between the glass panels and remain clean forever.

Window Walls

Hawaiian and other tropical resorts began using moveable glass walls long ago. This allows entire wall sections to open “Alfresco-style” from floor to ceiling, and wall to wall. Occupants enjoy the outdoors while sitting at the dining table or lounging on a couch in the living room. The glass wall can easily slide closed in bad weather and never interrupt the view.

Residential architects have begun including engineered glass walls into dream home applications. As a result they were very much on the “must-have” list for most custom home designs by 2017. When incorporated into the overall design, nothing takes advantage of gorgeous views better than disappearing walls of glass. And to further reinforce the experience, even the floor and ceiling tracks should be minimal, or better yet, invisible.

Glass walls are not inexpensive features. Achieving the zero threshold appearance requires a unique water-proofing system. Also, larger openings require special engineering to support the weight above properly. These certainly add more work and cost, but the result is spectacular.

At first window-walls were fairly rare and only available from specialty companies. But now almost every major window maker offers ultra-large glass wall systems. These are basically giant sliding doors. Sizes are more restricted but they can provide a similar appearance at an affordable price. Above is an example of just such an application and you can see why these large window walls are so popular.

Summary

Windows are a permanent part of a building’s structure and architecture, and are no longer simply replaceable fixtures. Windows and IGUs are now integral parts of the home that provide protection, light, visibility, ventilation and egress.